Gfg Serieshigh Efficient Boiling Dryer for Agrochemical Industry

Basic Info

Model No.: GFG

Product Description

Model NO.: GFG

Operational Method: Continuous

Drying Medium: Air

Heating Mode: Transmission

Type of Flow: Contra-Flow

Sprayer: None

Material: Stainless Steel

Capacity: 60-500

Transport Package: Wooden Box

Origin: Jiangsu, China

Structure: Fluidized Bed Drier

Operation Pressure: Atmospheric Dryer

Appearance of Dried Sample: Powder, Granules, Bulk

Movement Way: Combined

Type of Atomization: None

Application: Industries

Warrenty: One Year

Trademark: ZHENGAN

Specification: Customized

HS Code: 8419399090

GFG SeriesHigh Efficient Boiling Dryer

WORKING PRINCIPLE

The purified and heated air is introduced from the bottom by the draft fan and passed through the screen plate. The fluidization is formed through stirring and negative pressure in the working room. The moisture will be rapidly evaporated and exhausted so the material can be dried very fast.

FEATURES

The structure of fluidization bed is round so it is smooth inside without cleaning dead corners.

There is a stirring device inside of the hopper which can avoid agglomeration of wet material.

The granule is discharged by tipping over the hopper. The discharged system can be designed as per customer requirements.

The dryer is operated at the negative pressure and seal conditions. The air is filtered before enters to the dryer. Therefore, it is simple in operation and convenient in cleaning.

The drying speed is fast and the temperature is uniform. The drying time is normally 20~30 minutes for each batch.

APPLICATION

This dryer is widely used for the following materials:

Damp granules and powder materials in pharmaceutical, foodstuff, feed, chemical, and agrochemical industries.

Granules made by extruder, oscillating granulator, and high speed mixing granulator.

Special large granule and small blocks that having adhesive property.

The material that changes volume during drying process; such as konjak.

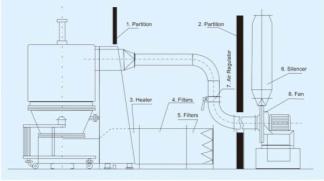

SCHEMATIC STRUCTURE

1. Partition

3.Heater

4.Filters

6.Silencer

7.Air Regulator

8. Fan

TECHNICALPARAMETERS

| Item | Model | ||||||

| Feeding Capacity(kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan Power(kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 |

| Stirring Power (kw) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Stirring Speed (rpm) | 8~11 | ||||||

| Steam Consumption (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Working Time(min) | 15-30(According to the material properties) | ||||||

| Dryer Height(mm) | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |

If you are interested to learn more about our products, please feel free to contact us:

| Contact Information | |

| Company Name | Jiangsu Zhenxing Drying Equipment Co.,Ltd. |

| Contact Person | Carol Ding |

| Mob | 0086-159-6129-8220 |

| TEL | 0086-519-85257376 |

| FAX | 0086-519-88670178 |

| Website | www.drying-equipment.CN |

Contact us if you need more details on Hot Air Dryer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Industrial Dryer、Fluid Bed Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Boiling Dryer > GFG Series High-Efficient Boiling Dryer

Other Products

Hot Products

Drying Machine Drying Oven (CT-C series)Lzg Series Helix Vibrstion DryerGMP Pharmaceutical Drying OvenFzg Square Static Vacuum DryerSzg Series Double Cone Rotary Vacuum DryerHg Series Cylinder Scratch Board DryerZpg Vacuum Harrow DryerPlg Series Continous Disc Plate DryerZlg Series Vibration Fluidized Bed DryerDwt Series Dehydrated Vegetables Processing Belt DryerDrying Hzg Series Rotary Drum DryerJyg Series Hollow Paddle DryerXzg Series Spin Flash DryerKbw Series Hot Air Circulation Tunnel Dryer for Spice PepperCT-C Series Drying Equipment Drying OvenHigh Quality Dw Series Mesh Belt Dryer